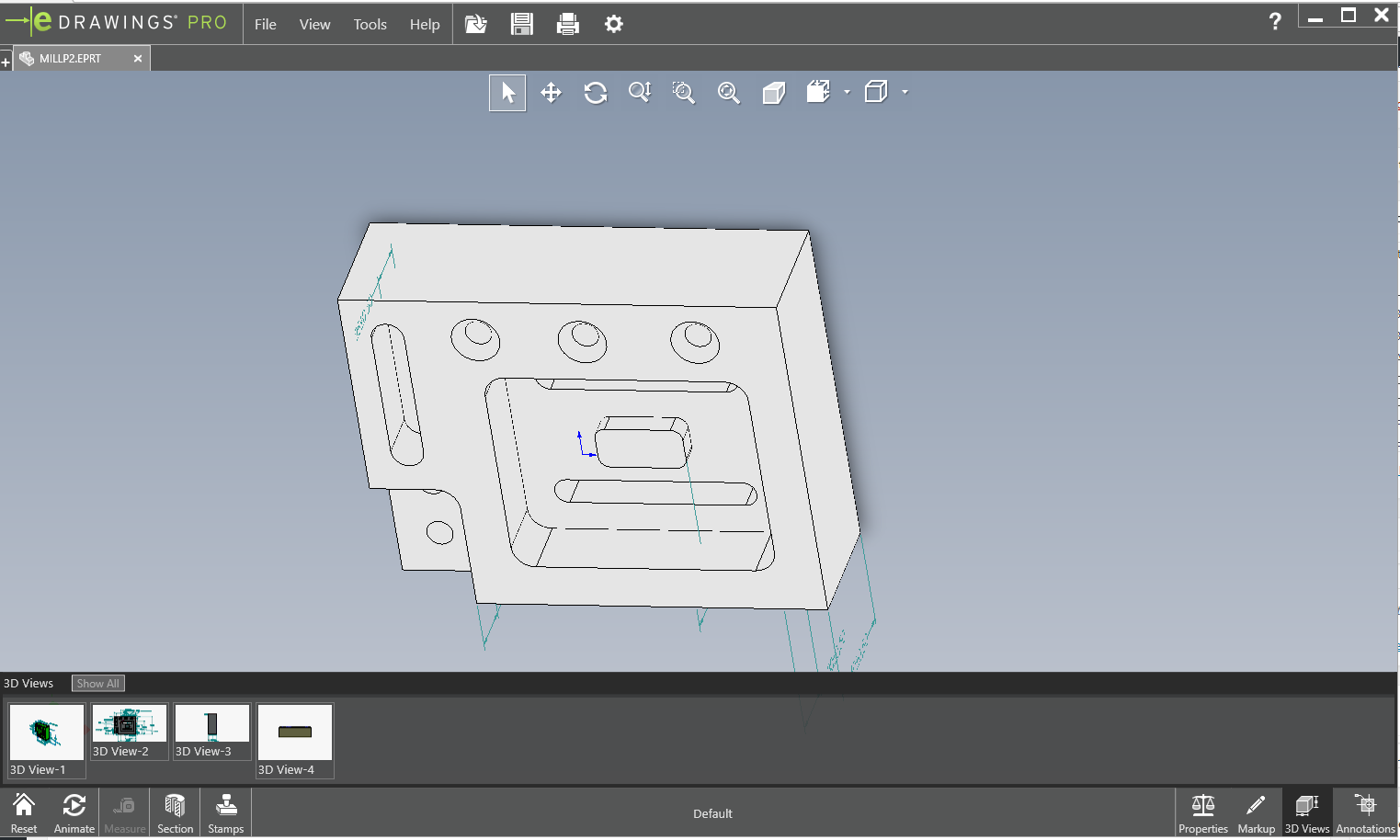

In other words, these intelligent annotations can automate the Numeric Control (NC) code programming one step further than the model itself. The models and requirements in annotations are integrated for easier reading.įurthermore, the tolerances and surface finishes can be consumed and acted upon by the SOLIDWORKS CAM software so that you don’t have to manually read or type them. In contrast, in a model-based environment, you can read everything in one place as shown in Figure 3 without having to switch back and forth between different documents. The back-and-forth switching between models and drawings not only slows down the process, it also introduces potential human reading or typing errors. For example, in a conventional way of Computer-Aid Manufacturing (CAM), a manufacturing engineer programs based on a model directly, but he or she has to read separate drawings to exact the tolerances and surface finishes, and then go back to the model and manually type in these requirements into the CAM program. Multiple toolpaths will generate simultaneously and at the same time the user can continue working in other areas or on other CAM models.MBD can also improve manufacturing efficiencies. Provide the ability to generate toolpaths as separate threads and in separate processes.CAMWorks can calculate a single pass or multiple passes for engraving. The curve project cycle removes material by projecting 2.5 Axis engrave or curve features on the 3 Axis feature.Rest machining is used to reduce air cutting by restricting toolpaths to areas within the feature that have not been machined previously.

All 3 Axis milling operations support rest or leftover machining.Z Level/Constant stopover combination operation can be used for machining steep and shallower slope areas in one toolpath.3 Axis finishing operations include parallel slice cut, constant stepover, Z-level, curve project, and others.This can reduce machining time up to 40% over conventional roughing with less wear. Adaptive roughing strategy provides the ability to cut using the full depth of the tool and safely run your machine at optimum speed.Some of the machining features included are:

0 kommentar(er)

0 kommentar(er)